CASE STUDY PAINT MANUFACTURERS

The paint is mixed, has an optimum consistency and now needs to be filled into paint cans or buckets in exact portions. Many paint manufacturers use very individual solutions for this – often a ladle is still used for decanting high-quality paints. Not only the issue of ergonomics, but also process reliability sometimes falls by the wayside, especially with older filling and decanting systems. The Eislingen-based printing ink manufacturer Zeller + Gmelin has equipped its system with a container lifting, tilting and dumping device from VENTZKI. These devices can be tilted electro-hydraulically up to 45 degrees and ensure safe work processes with higher productivity.

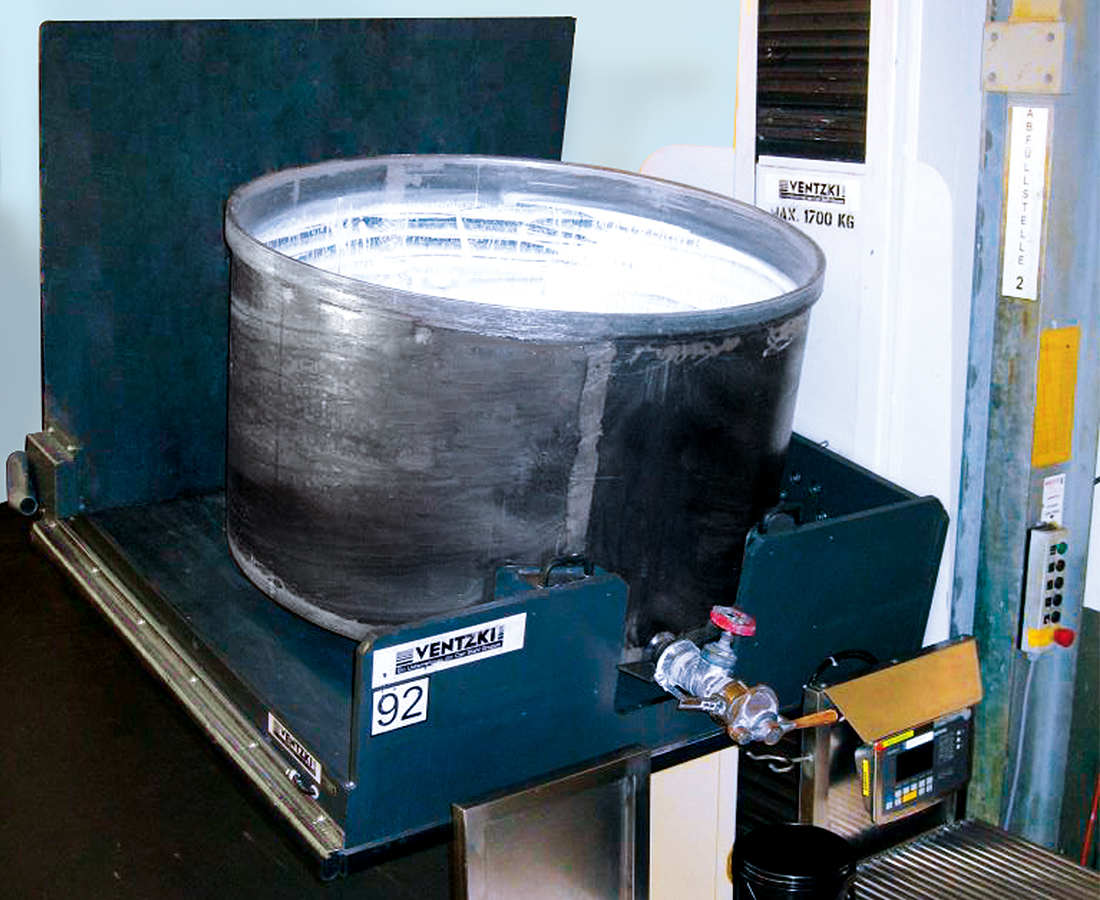

The printing ink manufacturer from Eislingen uses the VENTZKI lifting and tilting device for ergonomic work processes in decanting. Device types with the designation HNE are used here for containers up to two tons. This allows containers and pallets to be lifted up to 1,600 mm and tilted 45 degrees on one side. Round or square containers are placed on top using a forklift truck or hand pallet truck. The under-step protection and an adjustable tilt limit of 30 degrees make it safe to use. The lifting range is covered by a bellows, and the lifting and tilting position can be stopped in any position using the dead man’s switch.

While the basic design of the lifting and tilting devices is the same, VENTZKI offers individual devices with different chutes, unlike other common solutions on the market. If required, there are container stops on the loading and filling side or cut-outs, e.g. for a filling tap

Zeller + Gmelin works with a load handling device measuring 1,400 x 1,400 mm on a system that can be operated entirely by one employee. After all, the system is operated using a hand switch with a magnetic holder on the lifting column. However, operating elements on the cable or by foot switch are also possible.

The devices comply with all applicable machine requirements and are CE-compliant. The “plug-and-play” device delivery only requires a 16 A plug (5-pin, heavy current) on the user side. They are supplied fully wired, including the control unit, and VENTZKI can also carry out installation on request.

Even after a short time, it has been confirmed that the decanting device makes the work of manual filling easier. Paint manufacturers – whether of wall paints, varnishes or printing inks – who are already using VENTZKI tilting and dumping devices comment on this with increased efficiency and reduced workload in filling.

Not only Zeller + Gmelin, but also the printing ink manufacturer Hartmann (Nuremberg) and the paint manufacturer Brillux are already using the lifting and tilting devices for ergonomic work processes in decanting. Brillux uses a VENTZKI dumping device for containers up to two tons. The containers are positioned using a forklift truck.

A drum on rollers or a forklift as a load handling device on the dumping system – such individually manufactured filling equipment is not uncommon in the paint industry. Although they work, they do not correspond to a modern, fatigue-free and effective work process.

At paint and varnish manufacturer Brillux, the use of the NEE electro-hydraulic container tilting and dumping unit from VENTZKI has made it possible to perfectly coordinate the production process for filling more than 12,000 items from the full range. The new ergonomic decanting machine is compact, ensures safe working and increases productivity. This is because it is available in all positions required for a fatigue-free work process – steplessly and without interrupting work. It can be used to electro-hydraulically tilt containers with bulk material up to an angle of 135 degrees and fill the 10 to 20 liter containers with paint.

Load capacity 1.000 kg

Loading direction fromt the front or sideways

Loading height 150 mm

Useful height 600 mm

Load receptacle (BL x LL) 1.250 x 1.050 mm

Tilting 1 x 45° oder 2 x 45°

Power ratings 400 V / 50 Hz / 1,1 kW

The following applies to all device types:

With manual switch loosely attached to the cable or permanently installed on the lift mast

Other load handling attachments and container locks on request