CASE STUDY ASSEMBLY WORKSTATIONS

Safety and ergonomics are becoming increasingly important factors in the manufacturing industry. Accident-free working reduces follow-up costs, ergonomic workplaces reduce the downtime of expensive skilled workers. With the special developments of lifting, turning and tilting devices from VENTZKI, loads weighing several tons can not only be picked up, but also fixed with pinpoint accuracy. This means that work at assembly stations can be carried out safely in an ergonomically perfect position.

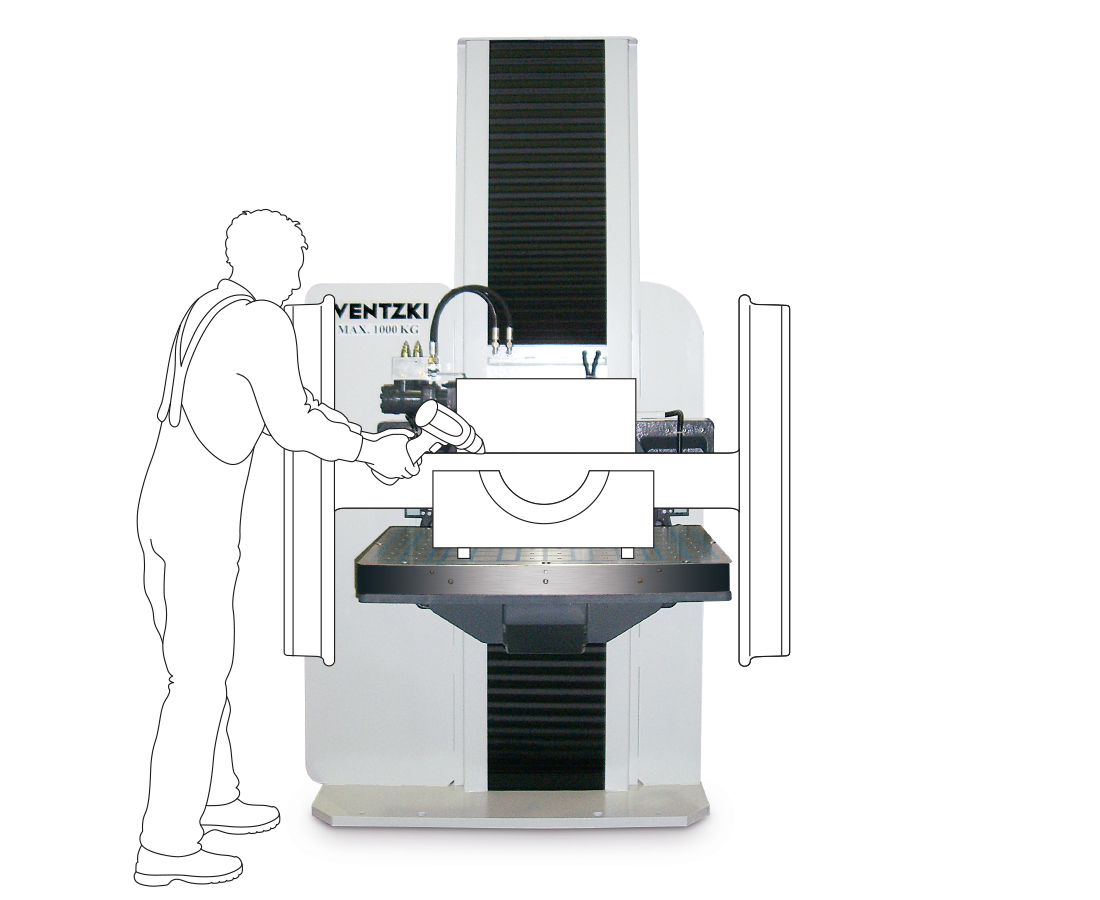

VENTZKI has developed such a lifting and rotary device especially for service and maintenance work for a locomotive gearbox manufacturer. This is a special version based on the existing HNE 2000 device type, which can lift gearboxes weighing up to two tons up to 600 millimetres in height. In addition, the final drives can be tilted up to 90 degrees to the right or left with the VENTZKI device. This means that they can be brought into the optimum position for the next work step. This promises a more ergonomic and at the same time safer assembly.

The increased safety of this type of device is primarily ensured by the load handling device – an individual platform that is precisely tailored to the workpiece, in this case the final drive. The gearboxes are placed on it. The platform has a number of holes and sleeves adapted to the workpiece. The gearbox is attached to these so that it is held securely on the platform. In the past, employees had to wedge the workpieces on a work table. The risk of accidents at work due to the gearbox slipping was significantly higher than with the VENTZKI special devices.

Once the gearbox is securely attached to the lifting and turning device, spare parts can be easily fitted or wheels balanced in any position. Working with it is much more ergonomic, safer and more productive. The lifting carriage, along which the workpiece is brought to the correct height, is covered with bellows.

The speed at which it is moved upwards, downwards or sideways is controlled individually by the employee, as the lowering speed can be adjusted via a throttle valve. The lifting and rotary device is operated via a limit switch and can be controlled via a dead man’s switch.

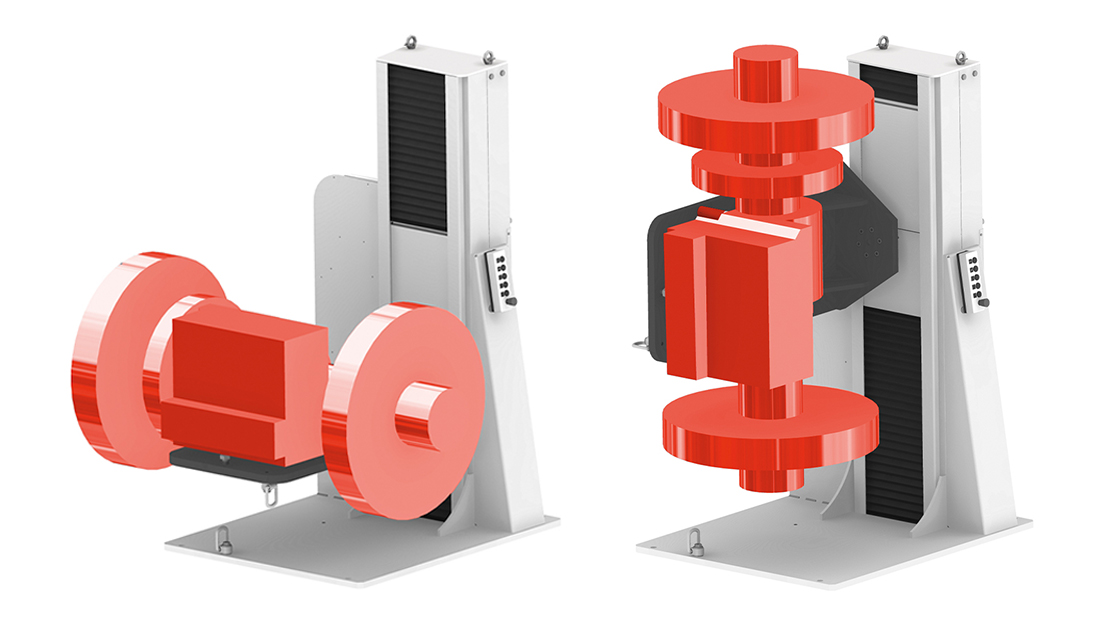

The special version of the lifting and rotary device for assembly stations is based on the HNE 1000/2000 stationary lifting and tilting devices. These high-quality handling systems are also driven electrohydraulically and are indispensable in the development, production and assembly of a wide range of products. They can lift pallets and large containers weighing up to two tons by 600 millimetres.

While the basic design of the lifting and tilting devices is the same, VENTZKI offers devices that are tailored directly to the requirements of individual companies, unlike other solutions available on the market. This means that the lifting and tilting device can be used for any heavy workpiece that needs to be brought to a certain position above the ground for assembly or repair. Be it an engine weighing several tons or another heavy piece of equipment – regardless of its weight and size.

Assembly work can be carried out in any position in a healthy posture and without tiring. The lifting movements of the containers can be selected separately and their tilt angle can be infinitely adjusted without interrupting work. The devices are equipped with safety devices such as line breakage protection and pressure relief valves.

Load capacity 1.000 kg

Loading direction fromt the front

Loading height 800 mm

Useful height 800 mm

Rotation 180°

Power ratings 400 V / 50 Hz

Surface finish Paint

Load capacity 600 kg

Loading direction from the front

Loading height 400 mm

Useful height 600 mm

Rotation 180°

Power ratings 400 V / 50 Hz

Surface finish Paint