CASE STUDY AUTOMOTIVE INDUSTRY

Ergonomic workplace design plays a major role in vehicle production. Improved working conditions at machines and production lines should make it possible to work in a way that is easy on the body. Car manufacturers such as Audi, BMW, Mercedes and VW use technology from VENTZKI for this purpose. The Eislingen-based company specializes in ergonomically designed and universally applicable lifting and tilting devices, which also ensure more efficient assembly.

Ergonomics refers to the optimization of work processes and equipment in order to protect workers from fatigue or even long-term damage to their health. In the field of production and assembly work, vehicle construction is primarily concerned with the optimal spatial arrangement of components. When removing them from immobile containers, unhealthy postures are often adopted in order to reach all parts. This is because the more components to be installed are removed from the container, the deeper the employee has to reach. The aim of sustainable workplace design is to prevent unbalanced postures from causing damage to health over many years of performing the same tasks.

In Baden-Württemberg, VENTZKI develops and manufactures high-quality handling systems for global players in the automotive industry. Thanks to their lifting and tilting function, the devices can be ergonomically adapted to the human posture and provide relief for the spine and musculoskeletal system. Demographic change is also making ergonomic workplace design a relevant topic in work organization. Car manufacturers, not only in Western Europe, are expecting the average age of their workforce to rise in future. VENTZKI offers its portfolio of handling devices to help employees stay healthy as a precautionary measure.

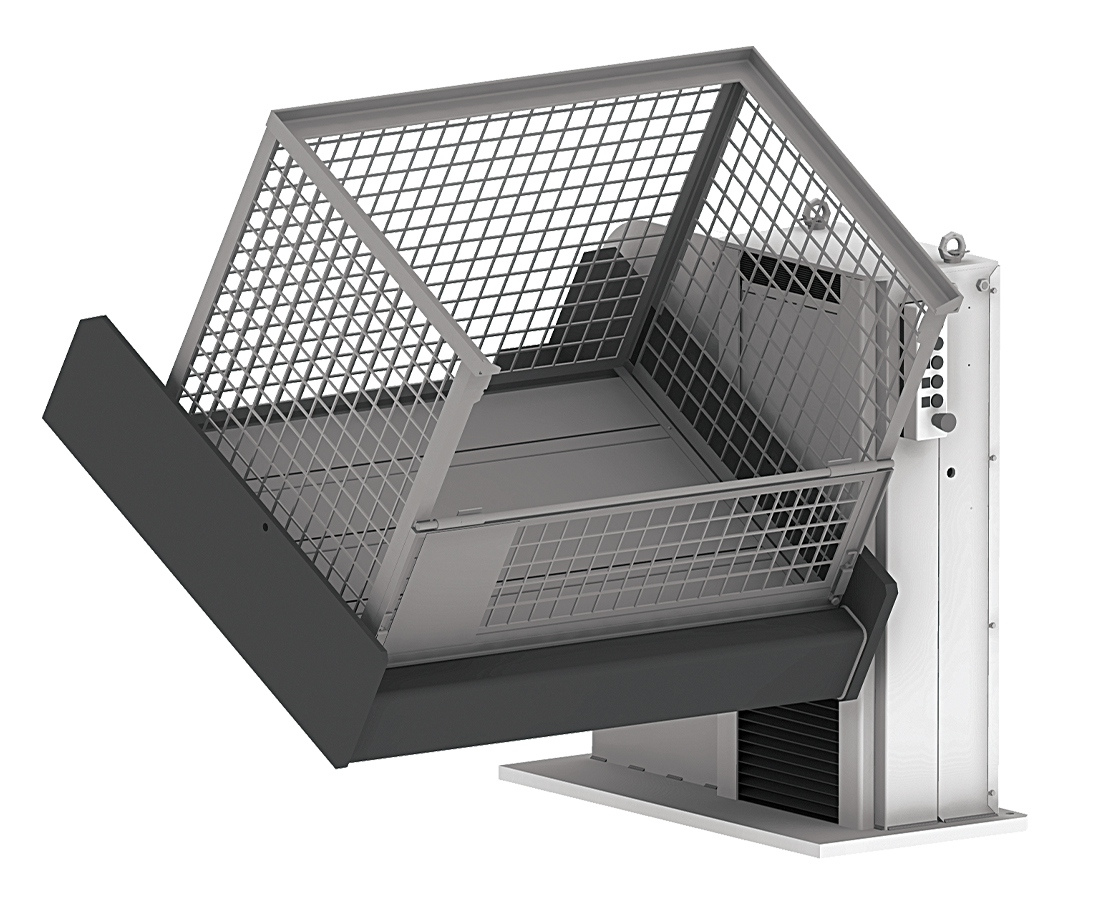

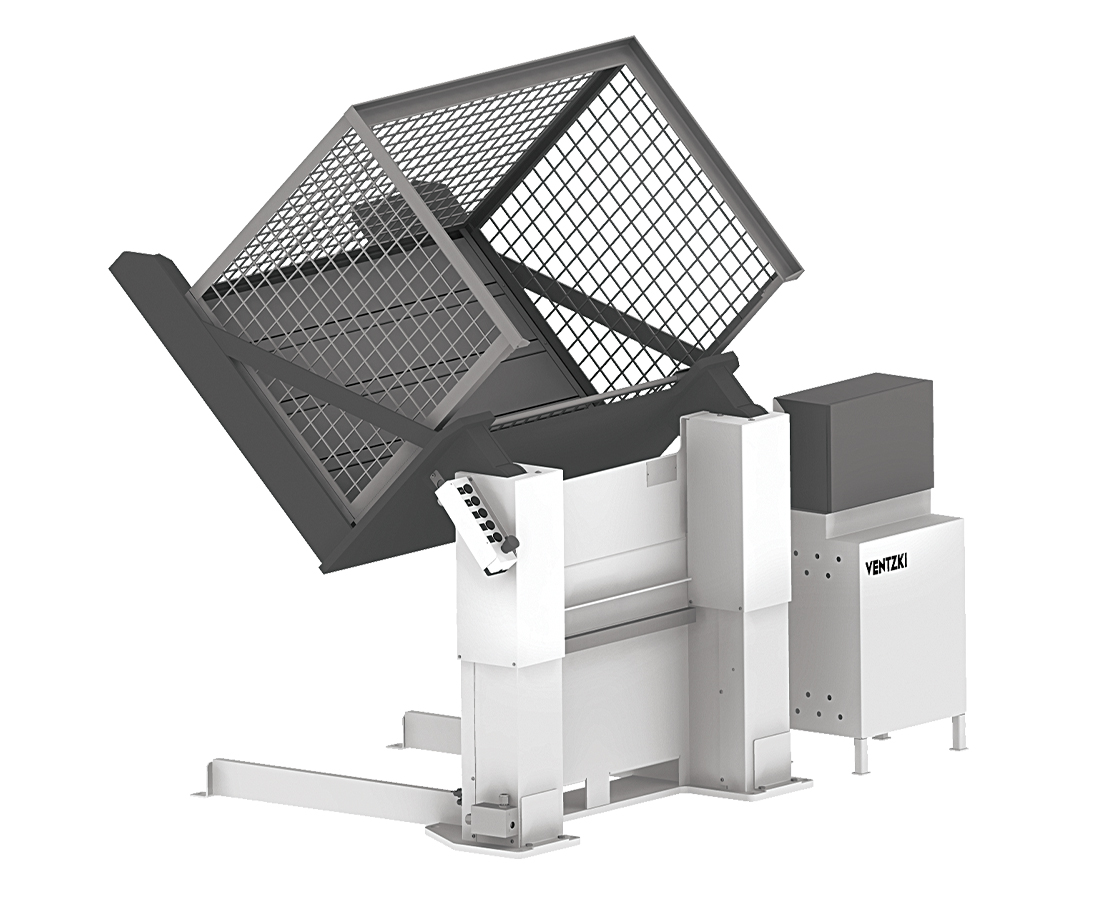

Premium manufacturers in the automotive industry already use lifting and tilting devices as well as scissor lift tables from VENTZKI. The ergonomic handling systems enable materials to be removed at working height, making work processes and material flow more efficient. They are designed for lifting and tilting containers and pallet cages and are universally aligned.

Container tilting devices are used in production at Mercedes and VW at the German sites, for example. BMW and Audi use devices with a combined lifting and tilting function. Both types of device facilitate and speed up work processes on the assembly line: even with a slight tilt, the entire contents of the containers can be reached in an upright posture. The tilt function prevents the user from having to bend down frequently.

The tilt angle of the standard devices is 45° to 90°, with a load capacity of up to two tons and a maximum effective stroke of 600 millimetres. They can be loaded from the side or from the front. The mobile or stationary devices are suitable for all types of pallets and containers and can be used in most production areas thanks to their electro-hydraulic or hydro-pneumatic drive.

Scissor lift tables from Ventzki are used to compensate for height differences in BMW production, for example. This makes it much easier to load and unload heavy loads and feed in materials without causing physical strain. Differences in height are no longer a question of strength. They are equipped with an electro-hydraulic drive as standard, but are also available in a hydro-pneumatic version. Designed for loads of up to six tons, the devices guarantee a long service life and a high level of work safety.

Lifting and tilting devices

Scissor lift tables

Load capacity 2.000 kg

Loading direction from the front

Loading height 150 mm

Useful height 600 mm

Load receptacle (B x L) 1.250 x 1.050 mm

Tilting 1 x 45° or 2 x 45°

Power ratings 400 V / 50 Hz /1,1 kW

Operation by means of a manual button loosely attached to the cable or permanently installed on the lift mast

Other load handling attachments and container locks on request

Load capacity 2.000 kg

Loading direction from the front

Loading height 150 mm

Useful height 300 mm

Load receptacle (B x L) 1.250 x 1.050 mm

Tilting 90°

Aggregate arrangement external hydraulic power unit

Power ratings 400 V / 50 Hz / 1,1 kW

Load capacity 6.000 kg

Platform (BP x LP) 1.300 x 2.500 mm

Useful height 1.600 mm

Lift time 40 sec.

Construction height 450 mm